Copyright. © 2023 Cryogas Asia

Liquid Nitrogen LN2 Dosing in Food & Beverage, Personal care product packaging: enhancing quality, shelf-life, consumer satisfaction, and environmentally friendly.

Introduction:

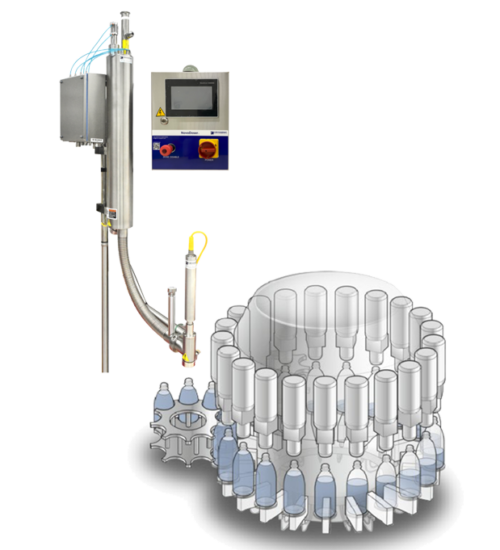

Maintaining product quality and extending shelf life are critical objectives in the food, beverage & personal care industry. To achieve these goals, innovative techniques are continuously being developed. One such technique gaining popularity is liquid nitrogen dosing, which involves the controlled injection of liquid nitrogen into product containers during the packaging process.

Liquid nitrogen dosing is considered one of the most significant cryogenic technology adaptation, which not only benefit many industries in their cost reduction and quality improvement in product packaging, but also the environment.

Liquid nitrogen dosing offers a wide range of advantages for product packaging. Let’s explore some of the key benefits.

By displacing oxygen, liquid nitrogen dosing effectively prevents oxidation and the growth of spoilage microorganisms. This preservation technique helps maintain the freshness, taste, color, and nutritional value of beverages. It is particularly beneficial for oxygen-sensitive products like juices, wines, teas, nuts, flavored health supplements, and carbonated drinks.

Nitrogenation enhances product creaminess and creates a captivating cascading bubble effect during pouring. Nitrogenation also reduce dissolved oxygen content in the product.