Copyright. © 2023 Cryogas Asia

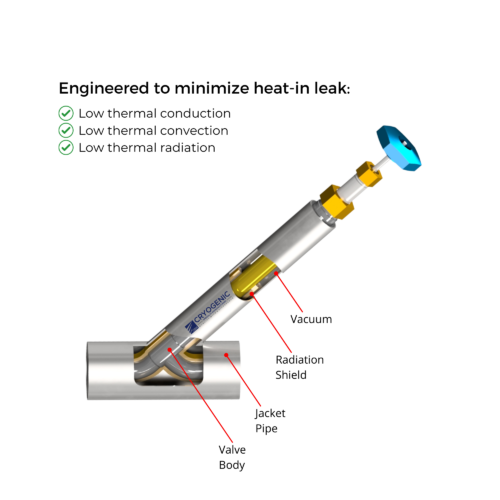

Cryogenic valves are important components to isolate or regulate the cryogen flow in the pipelines. CSM manufactures the valve with vacuum jacketed insulation to minimize heat leaks into your cryogenic system. CSM products come in two options for vacuum insulation: static and dynamic vacuum types. To understand which vacuum insulation fits your needs, please click on the link “Dynamic Vacuum vs Static Vacuum.”

CSM Cryogenic’s valve solutions incorporate advanced super insulation features for optimal efficiency and thermal insulation. By using our valve, you can mitigate heat leaks, improve efficiency, and reduce costs in cryogenic liquid transfer. Trust CSM Cryogenic’s expertise for reliable and efficient solutions in your cryogenic liquid transfer needs. To understand how our super insulation work to reduce your heat leaks, click on the links “Super Insulation Technology“ and “Heat Leak – Value Vs Cost.“

The valve is available in manual operation or pneumatic actuation. On top of that, CSM valves comes with advanced close tolerance bayonet connections that guarantee frost and condensation-free operation, with the lowest heat leaks, preserving your cryogenic fluid at the lowest temperature and ensuring pressure stability. To understand our bayonet technology and how it will benefit your cryogenic system, please click on the link “Close Tolerance Bayonet Technology.“

Compared to traditional foam insulated cryogenic valve, the heat leaks performance is 20 to 40 times better. The resulted LN2 saving will generate ROI for the valve in 6 months.

The valves are usually welded to the vacuum jacketed pipe forming part of a pipe spool, or it could be supplied as modular component for greater installation flexibility in your cryogenic system.

CSM VJ-valve comes with 10,000 life cycle for leak tight shut-off performance. The valve seat and stem seal meet leak tightness requirement of ANSI FCI 70-2 (superseding ANSI B16.104) class VI.

Every CSM valve comes with 3 years vacuum warranty. All wear and tear parts are availble in stock for immediate delivery.

CSM vacuum jacketed modular valves and fittings can be used in combination with Semi-Flex hoses to provide increased flexibility and reduce lead times in your cryogenic piping project.

|

Reusability | : | Modular vacuum jacketed valve & fitting can be easily dismantled and reused when the piping system is reconfigured |

|

Time Saving | : | With readily available stocks and short lead times, projects can be completed early and production can start up promptly. |

|

Cost Saving | : | Modular design makes addition of new spools or individual spool replacement possible, resulting in lower system expansion and maintenance cost |