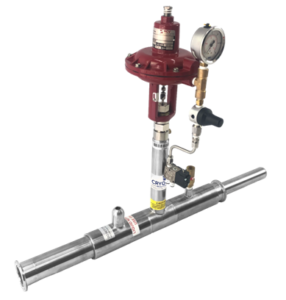

CSM vacuum insulated valves are recommended when system efficiency and elimination of frost, ice and moisture are essential. The initial cost is greater for the vacuum insulated option, but the savings outweigh the investment in less than a year.

By using a vacuum insulated valve, one can expect a maintenance free operation that does not require frequent replacement of PU foam insulation. Vacuum insulated Modular Valve guarantees extremely low heat leak for minimum liquid boil-off compared to foam-insulated valve by at least 20 times. Thus liquid vaporization loss is reduced and liquid quality is maintained up to the point of use.

Modular valves are commonly used in both Stati-Rigid and Semi-Flex piping systems with Dynamic or Static vacuum technology.